CASE STUDY SNAPSHOT

Customer : A leading Beverage manufacturer handling large volumesSize : >200-1000

Project vertical : Industrial

Challenge : Manage data flow precisely and quiclly in a cost-effective manner

Solution : Design and develop an Industrial Internet of Things (IIoT) gateway and leverage existing PLCs

Services & Products Availed : Product engineering services, IoT Gateway Development, Industrial Gateway

Tools and Technologies :

- Key Hardware: Renesas RL78/G13

- Software Development: C

- Frameworks: Renesas CS+

- Interfaces: RS485, 4-20 mA

INTRODUCTION

A prominent beverages manufacturer needed to upgrade its plant's efficiency by implementing a precise, automated, and multi-channel liquid flow control system. They required a cost-effective solution that could integrate with their existing infrastructure to manage complex fluid dynamics during processing, a core challenge in industrial automation.

CHALLENGE

The client's facility utilizes 16 distinct pipelines, each critical for different stages of beverage processing. While digital flow meters were installed, their existing PLC (Programmable Logic Controller) was already operating at maximum capacity and lacked the necessary I/O channels to simultaneously monitor 16 high-frequency pulse outputs from the meters. The primary challenge was to develop a system for precise flow measurement and control without the prohibitive expense of adding a second PLC. The solution needed to be robust, accurate, and capable of seamless integration into a high-demand industrial environment.

SOLUTION:Custom Industrial Gateway for PLC Integration

Embien Technologies delivered a tailored, end-to-end solution centered around a custom-developed industrial IoT (IIoT) gateway. Our approach combined deep analysis, strategic hardware design, and intelligent firmware development to overcome the client's limitations.

On-Site Analysis and System Architecture

Our engineering team began with a detailed on-site analysis of the client's plant. We identified that the existing digital flow meters, which use pulse outputs, were ideal for accurate measurement. The key bottleneck was the PLC's inability to handle the high-volume, simultaneous data streams. Based on this, we proposed a cost-effective architecture: a dedicated multi-channel pulse counter gateway that would act as an intelligent bridge between the 16 flow meters and the single PLC.

Custom Gateway Development with Renesas RL78/G13

The core of our solution was a purpose-built gateway device. The main technical hurdle was selecting a microcontroller (MCU) capable of simultaneously counting 16 independent pulse channels without data loss. Many MCUs have numerous input pins but share a small number of internal timers, making them unsuitable for this task.

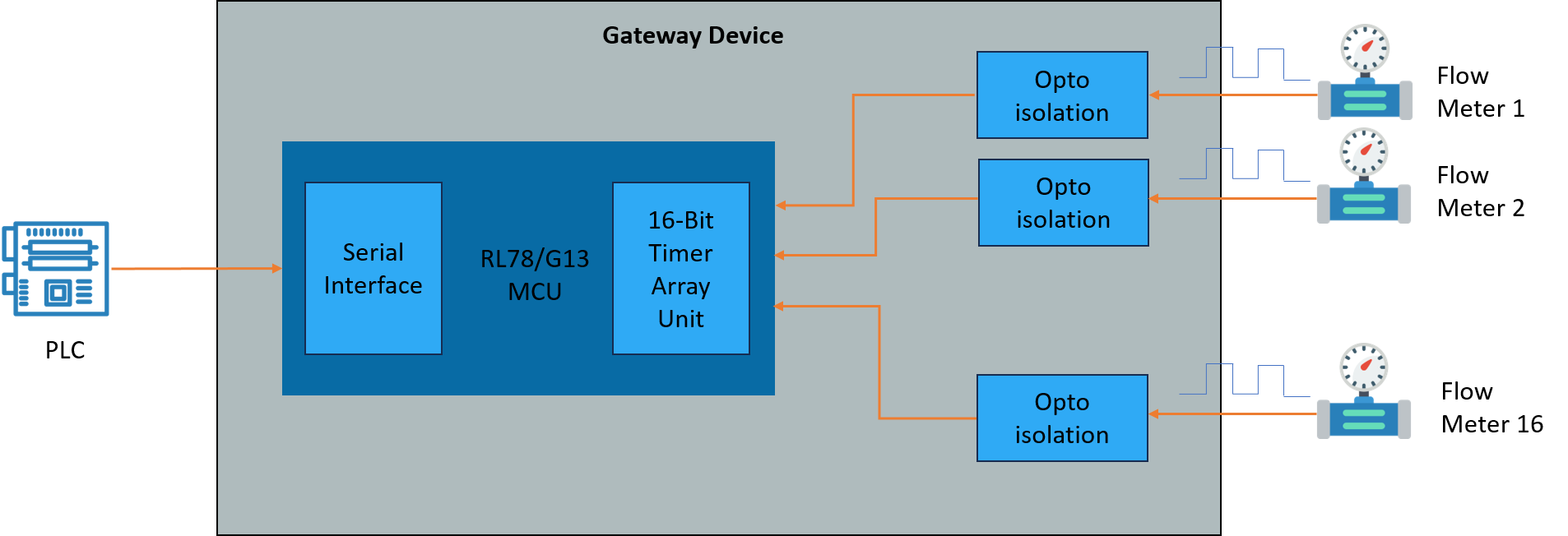

The block diagram of the devices is captured below.

After a thorough evaluation, we selected the Renesas RL78/G13 series MCU. This powerful and reliable industrial-grade processor was the perfect fit, featuring a 16-channel, 16-bit timer array unit that allows for true simultaneous pulse counting.

The gateway hardware was designed for the rigors of an industrial setting:

- Optical Isolation:Each of the 16 input channels was optically isolated to eliminate signal interference and protect the central MCU from electrical noise and power surges common in factory environments.

- Robust Connectivity:The device was equipped with standard industrial terminal connectors for easy, secure interfacing with the flow meters and a serial communication port (RS-485) for a reliable, long-distance connection to the PLC.

Intelligent Firmware and Data Processing

The firmware for the gateway was engineered to be highly efficient. Its primary functions were to:

- Simultaneously and accurately count the incoming pulses from all 16 flow meters in real-time.

- Convert the raw pulse counts into meaningful, standardized flow rate data (e.g., liters per minute).

- Transmit this processed flow data continuously to the PLC via the serial interface.

By offloading the intensive pulse-counting task to our dedicated gateway, the client's existing PLC was freed up to focus on its primary role: executing control logic.

Integrated Flow Management System

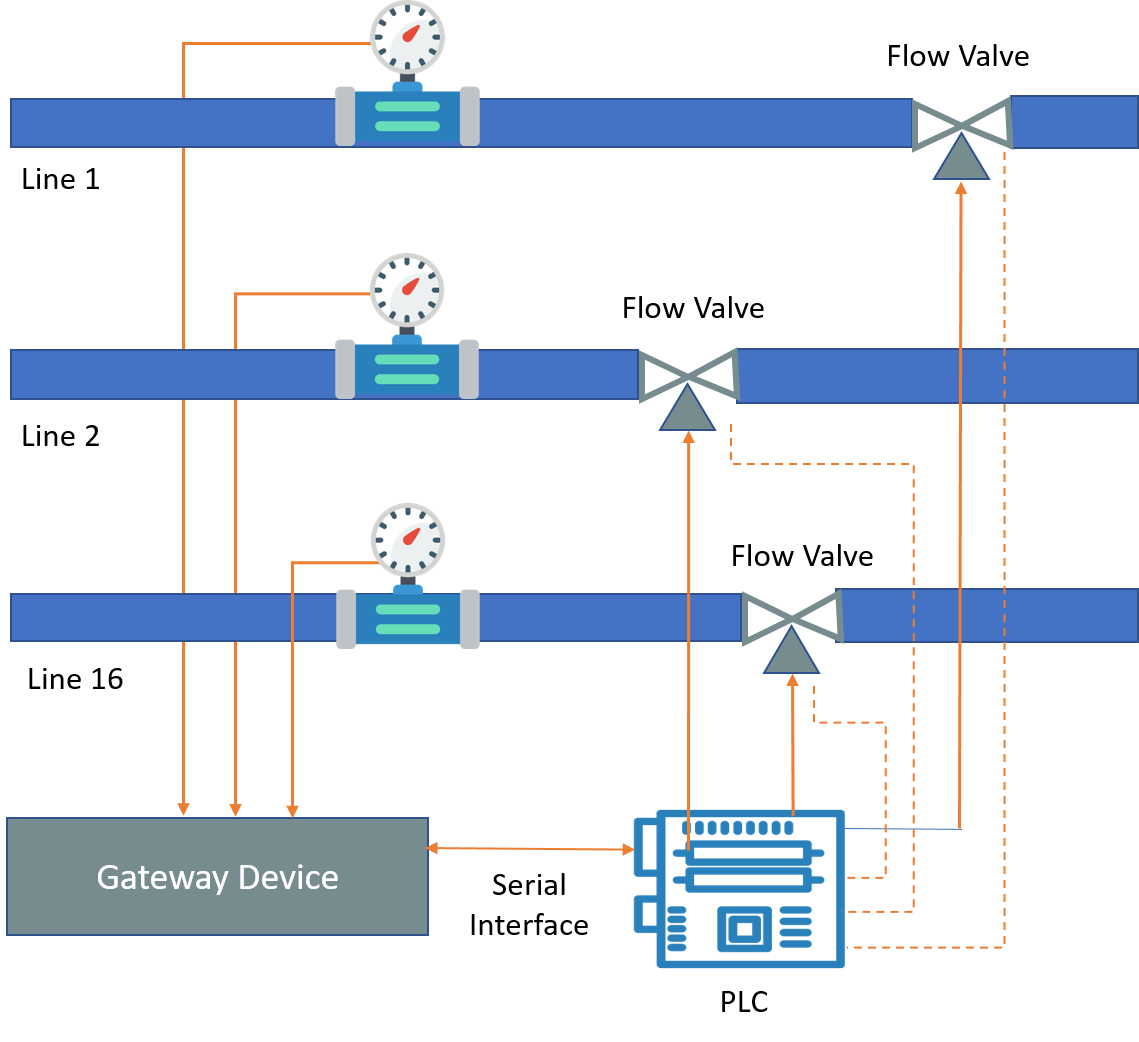

The following figure illustrates the setup at the plant for flow measurement and control

The complete, integrated system established a closed-loop control system for each pipeline.

- The PLC receives real-time flow data for all 16 channels from the Embien gateway.

- Based on pre-programmed setpoints for each stage of the beverage process, the PLC logic calculates the necessary adjustments.

- The PLC then sends control signals to automated flow valves on each pipeline, precisely opening or closing them to regulate the liquid flow.

- Feedback from the valve positions (via a 4-20mA analog signal) allows the PLC to verify the adjustments and perform corrective iterations, ensuring extremely high accuracy.

Our team provided full on-site support, installing the gateway and working with the client’s engineers to integrate it and thoroughly test the entire flow management system.

BENEFITS

- Significant Cost Savings:The custom gateway solution eliminated the need to purchase, install, and program an expensive secondary PLC, saving significant capital expenditure.

- Enhanced Process Accuracy:Enabled precise, real-time, and automated flow control across all 16 pipelines, improving product consistency and quality.

- Seamless Integration:Our solution was designed to integrate perfectly with the client's existing PLC and flow meters, avoiding costly downtime and infrastructure changes.

- Increased Operational Efficiency:By automating flow management, the system reduced the need for manual intervention and optimized the use of raw materials.

- Robust and Reliable Performance:The industrial-grade design with optical isolation ensures dependable, long-term operation in a demanding factory environment.

CONCLUSION

Embien successfully engineered and deployed a sophisticated flow control system that solved a critical challenge for our client in the beverage industry. By developing a custom gateway with the Renesas RL78/G13 MCU, we delivered a solution that was not only highly effective and precise but also exceptionally cost-efficient. This project is a testament to our expertise in creating targeted solutions for complex industrial automation requirements.

If your manufacturing process requires enhanced precision, control, or data acquisition, partner with Embien. Contact us to discover how our custom engineering services can revolutionize your operations.