CASE STUDY SNAPSHOT

Customer : An Indian Automotive Tier 1Size : > 200-1000

Project vertical : Automotive

Challenge : Create a fully digital instrument cluster that was both visually stunning and highly reliable.

Solution : Develop Renesas RH850 based cluster platform and leverage Sparklet for graphics

Services & Products Availed : Product engineering services, Sparklet, Flint

Tools and Technologies :

- Key Hardware: Renesas Rh850

- Software Development: C, Sparklet

- Frameworks: Flint

- Peripherals: TFT, Touch etc

INTRODUCTION

A leading Indian Automotive Tier 1 supplier, aiming to capture the growing market for premium two-wheelers, needed a feature-rich, graphically advanced TFT instrument cluster. They required a solution that delivered a smartphone-like user experience while meeting stringent automotive performance and cost targets, powered by a next-generation microcontroller.

CHALLENGE

The challenge was to move beyond traditional electro-mechanical dials and create a fully digital instrument cluster that was both visually stunning and highly reliable. This required developing a complex HMI with smooth animations, customizable themes, and smartphone connectivity on a resource-constrained embedded platform. The solution had to leverage the advanced graphics capabilities of the Renesas RH850 MCU to minimize CPU load and ensure real-time performance. A key requirement was an accelerated development cycle to bring the product to market quickly and demonstrate a clear technological edge over competitors.

SOLUTION

A High-Performance HMI with Sparklet GUI on Renesas RH850

Embien was chosen to design and develop a prototype for a next-generation two-wheeler instrument cluster, demonstrating a powerful combination of advanced hardware and our optimized graphics library.

The Evolution to Fully Digital Cluster

The automotive industry has seen a rapid shift from mechanical and electro-mechanical clusters to fully digital, TFT-based solutions. While traditional clusters were reliable, they were fixed in function and could not display the vast amount of information available in modern vehicles equipped with multiple ECUs. Early digital solutions added small LCDs, but today's riders, accustomed to smartphones, expect rich, configurable, and intuitive interfaces. Our goal was to deliver this premium experience in the highly competitive two-wheeler segment.

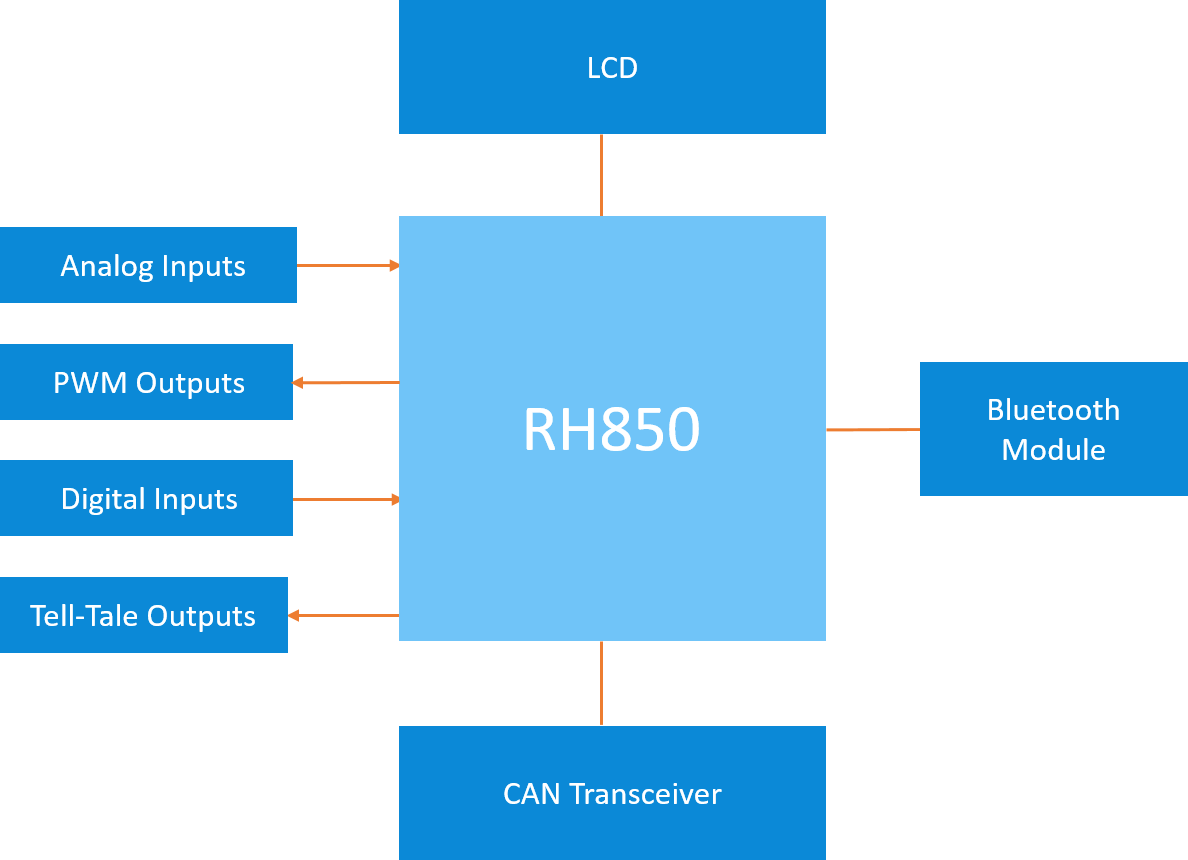

Harnessing the Power of Renesas RH850

The foundation of our solution was a custom hardware board built around the Renesas RH850 series of MCUs. This processor family is specifically designed for demanding automotive HMI applications. We leveraged its key features:

- Dedicated 2D GPU: The RH850 includes a powerful GPU, enabling us to offload complex graphics rendering from the main CPU core. This was critical for achieving smooth animations and transitions without impacting the real-time performance of the cluster's core functions.

- Multiple Display Layers & Sprites: The MCU supports up to four independent display layers and numerous hardware sprites. Our software architecture used these features to efficiently render different UI elements. For example, the background, digital dials, tell-tale icons, and pop-up notifications were all handled on separate layers, allowing them to be updated independently with minimal software overhead.

- On-chip Memory and Peripherals: With up to 2.5MB of internal SRAM and a dedicated JPEG decoder, the RH850 provided ample resources for storing graphical assets and display buffers, reducing the need for more expensive external memory.

The Sparklet GUI Library Advantage

To create the HMI, we deployed our proprietary Sparklet Embedded Graphics Library. Sparklet is highly optimized for microcontrollers like the RH850 and is designed to take full advantage of their hardware acceleration features.

- Efficient Rendering Engine: Sparklet's rendering engine was tailored to work directly with the RH850's GPU and layer-based display controller. This resulted in exceptionally low CPU utilization, leaving plenty of processing power for handling CAN communication, Bluetooth connectivity, and other application logic.

- Seamless Design Workflow with Flint IDE: All UI screens and assets were designed by graphic artists in Adobe Photoshop. These designs were then directly imported into our Flint IDE, a PC-based tool that bridges the gap between design and engineering. Flint allowed us to define animations, screen transitions, and logic, and then automatically generate optimized C-code and assets for the Sparklet library. This workflow dramatically reduced development time, enabling us to build the entire HMI in a matter of weeks.

Feature-Rich Hardware and Software Design

The prototype was a complete solution showcasing a wide range of features:

Feature-Rich Hardware and Software Design

- Flexible Display Support: The hardware was designed to support multiple LCD sizes (5” and 7”) with both 18-bit and 24-bit color interfaces.

- Vehicle Network Integration: A CAN transceiver was integrated to receive all vital vehicle data, such as vehicle speed, engine RPM, fuel level, and tell-tale warnings from other ECUs.

- Smartphone Connectivity: An external Bluetooth module, connected via UART, enabled a rich set of connected features, including incoming call alerts (with options to accept/reject), message notifications, and turn-by-turn navigation data streamed from a smartphone.

- Intuitive User Experience: The final HMI featured a modern design with smooth animations, customizable themes, and an intuitive menu system, all controlled by handlebar-mounted buttons.

BENEFITS

The customer received a powerful and market-differentiating solution with several key benefits:

- Accelerated Development: The combination of Sparklet and the Flint IDE reduced HMI development time from months to weeks.

- High-Performance Graphics: By leveraging the Renesas RH850's dedicated GPU, the cluster delivered smooth, high-quality graphics with very low CPU overhead.

- Advanced Connected Features: Integrated Bluetooth provided smartphone connectivity for calls, notifications, and navigation, a key feature for the premium market.

- Highly Customizable UI: The design supported multiple user-selectable themes, offering a level of personalization previously unseen in this segment.

- Production-Ready Design: The prototype served as a robust, feature-complete foundation for the customer's final production instrument cluster.

CONCLUSION

This project showcases Embien's ability to deliver cutting-edge automotive HMI solutions by combining our optimized Sparklet GUI library with powerful hardware platforms like the Renesas RH850. We successfully demonstrated a next-generation digital instrument cluster that met the high expectations of modern riders and provided our Tier 1 customer with a significant competitive advantage. Our expertise in embedded graphics and automotive systems enables us to turn visionary concepts into production-ready reality, fast.

For world-class digital cockpit and HMI solutions, partner with Embien to accelerate your development and redefine the user experience.