CASE STUDY SNAPSHOT

Customer : An OEM of industrial automation devicesSize : >51-200

Project vertical : Industrial

Challenge : Enable integration of IIoT with SCADA system in a legacy enviroinment.

Solution : Design and develop an Android IO Manager Module with ModbusTCP over Android.

Services & Products Availed : Product engineering services, Mobile App Development

Tools and Technologies :

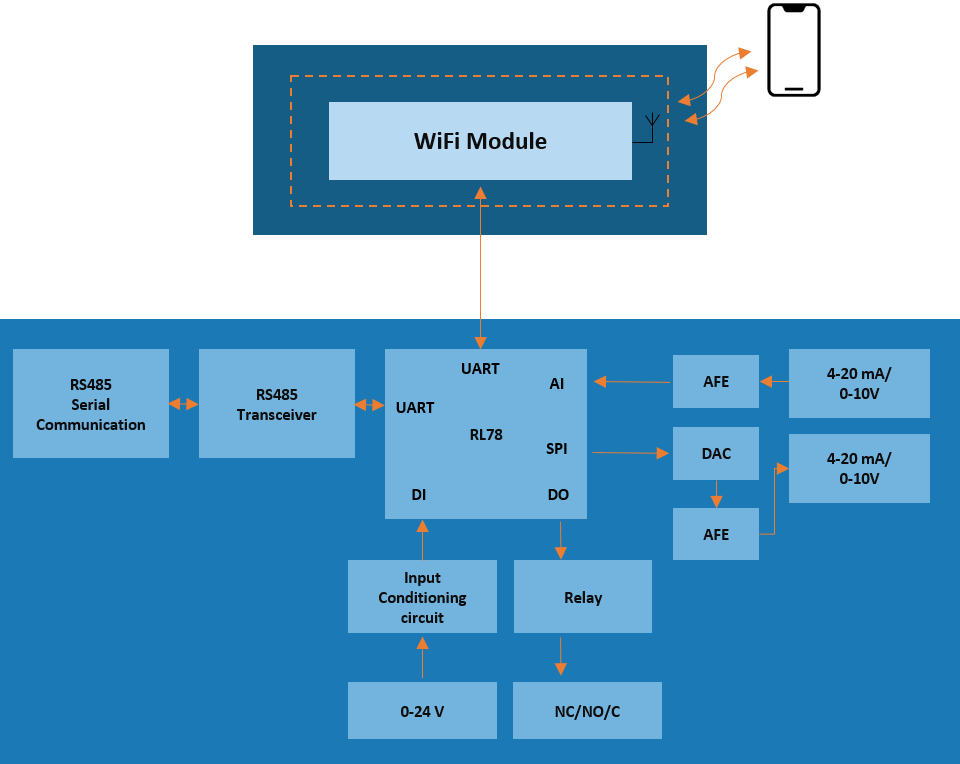

- Key Hardware: Renesas RL78

- Software Development: Java, C

- Frameworks: Android

- Frameworks: Wi-Fi, Ethernet, Digital IO etc

INTRODUCTION

A leading Industrial OEM in the fire and safety domain needed to modernize its multi-channel IO module. Their goal was to integrate wireless capabilities and provide a mobile management solution, enabling them to compete in the evolving Industry 4.0 landscape without alienating their existing customer base.

CHALLENGE

The core challenge was upgrading a legacy system built on a Renesas RL78 microcontroller with an RS485 Modbus/RTU interface. This system had limited expansion capabilities and was designed for wired networks. The OEM required a solution that introduced Wi-Fi and Modbus/TCP connectivity with minimal architectural changes to the existing, field-proven hardware. The upgrade had to be cost-effective, avoiding a significant price increase for the base model. Furthermore, the new system needed to be managed by a user-friendly mobile application and integrate seamlessly with their existing Windows-based SCADA software, ensuring a smooth transition for all users.

SOLUTION

A Multi-faceted Approach to IIoT Enablement

Embien devised a comprehensive strategy that addressed the hardware, firmware, and software aspects of the challenge, delivering a complete Android IO Module Manager solution. Our approach was centered on modularity, backward compatibility, and user experience.

1. Hardware Innovation: The Add-on Wi-Fi Module

Our engineering team began with a thorough analysis of the existing multi-channel IO module. We discovered an underutilized UART port originally intended for debugging. This became the key to our non-intrusive upgrade path. Instead of a costly and complex redesign of the mainboard, we proposed and developed a compact, add-on Wi-Fi expansion card.

This modular approach was a strategic decision with significant benefits. It allowed the OEM to offer two product variants: the standard wired module and a wireless-enabled version. This meant the cost of Wi-Fi connectivity was not forced upon customers who didn't need it, keeping the base product competitively priced. The add-on card handled the Wi-Fi communication and the translation between Modbus/TCP over Wi-Fi and the internal Modbus/RTU protocol, effectively acting as a smart gateway. We also analyzed historical on-field failure data for the previous generation product and incorporated enhanced safety and reliability mechanisms into the new hardware design to prevent known issues, a critical requirement in the fire and safety industry.

2. Intelligent Firmware Development

With the hardware path defined, our firmware team developed an intelligent and flexible firmware for the Renesas RL78 microcontroller. The primary feature was the automatic detection of the Wi-Fi add-on card.

Dynamic Functionality: Upon boot-up, the firmware checks for the presence of the expansion card. If the card is not detected, the system operates purely as a legacy Modbus/RTU device over RS485. If the card is present, the firmware dynamically activates the Modbus/TCP functionality and exposes additional Modbus registers specifically for Wi-Fi configuration (e.g., SSID, password, IP settings).

Backward Compatibility: We meticulously preserved the existing Modbus register map. This ensured that the upgraded module was a drop-in replacement for older units and worked perfectly with the client's existing Windows SCADA software without any immediate changes.

Power Optimization: The new firmware was also optimized for reduced power consumption, improving the overall efficiency and thermal performance of the IO module.

3. The Modbus TCP Android App: Centralized Mobile Control

The centerpiece of the solution was a custom-designed Modbus TCP Android App, built to serve as a powerful and intuitive Human-Machine Interface (HMI).

Effortless Commissioning: For initial setup, the IO module with the Wi-Fi card boots into an Access Point (AP) mode with a default network configuration. The Android app features a "commissioning mode" that allows an installer to connect their phone directly to the module's AP, configure it to connect to the factory's main Wi-Fi network, and switch it to client mode for regular operation. This simplified the deployment process significantly.

Rich, Configurable UI: The app provides a highly visual and interactive experience. We included a library of pre-configured widgets essential for industrial monitoring and control, such as:

- Line and Bar Graphs for trend analysis

- Meters and Seek Bars for real-time value display

- Buttons and Switches for digital output control

- Status Lights and Tanks for visual process representation

Plant Layout and Multi-Device Management: Users can create projects within the app and upload a layout of their plant or factory floor. They can then drag and drop widgets corresponding to different IO modules onto the layout, creating a customized and intuitive SCADA-like overview of their entire operation. The application was designed to manage multiple IO modules simultaneously over the network.

Interoperability: Because the app functions as a standard Modbus TCP Master, it is not limited to the client's IO modules. It can seamlessly communicate with and control other third-party Modbus TCP compliant devices like PLCs, VFDs, and other controllers within the same network, adding immense value and making it a central control hub. The app was rigorously tested across various Android versions and screen resolutions for maximum compatibility.

4. Seamless SCADA Integration

To complete the ecosystem, Embien assisted the client in updating their existing Windows-based SCADA application. By working on the specific software library that corresponded to the IO module, we added support for the new Wi-Fi configuration registers. This allowed users of the desktop application to configure and manage the wireless settings of the new modules, ensuring a consistent management experience across both mobile and desktop platforms.

Benefits

Accelerated IIoT Market Entry: The client was able to launch a modernized, wireless-enabled product quickly, meeting the demands of Industry 4.0.

Cost-Effective & Modular Upgrade: The add-on card approach provided a low-risk, financially viable upgrade path without increasing the Bill of Materials (BoM) cost for the base model.

Enhanced Operational Efficiency: The intuitive Android app with its visual layout and multi-device control capabilities drastically simplified monitoring, configuration, and management for field engineers.

Improved Product Reliability: By analysing past failures and engineering robust safety mechanisms into the design, the new system offered higher reliability and safety.

Protected Customer Investments: Full backward compatibility and seamless integration with existing SCADA software ensured that the client's loyal customer base could adopt the new technology without disruption.

Conclusion

Embien successfully transformed a legacy industrial product into a modern, IIoT-ready solution. By combining innovative hardware design, intelligent firmware, and a feature-rich Android application, we delivered a comprehensive system that exceeded the client's expectations. This project showcases our expertise in product modernization, embedded engineering, and custom software development for industrial automation. If you are looking to upgrade your existing products with wireless connectivity, mobile management, or other IIoT features, our team has the experience and technical skill to bring your vision to life and enhance your market position.