CASE STUDY SNAPSHOT

Customer : A Germany-based manufacturer of industrial automation solutionsSize : 51-200

Project vertical : Industrial IoT and embedded systems

Challenge : Develop a low-cost, secure Industrial IoT device for real-time monitoring and control of industrial parameters

Solution : ARM-based Industrial IoT Device Development with LoRa connectivity and AWS IoT Cloud Application

Services Availed : Turnkey Product Engineering, Embedded Application Development, IoT System Integration, Cloud App Development, Mobile App Development

Tools and Technologies :

- Hardware: NXP Kinetis KW40 - Cortex M

- Programming Languages: C, Java, Swift

- Hardware Design Tools: Altium Designer

- Software Development: Linux, GCC Toolchain

- Frameworks: FreeRTOS, REST API, OpenSSL, Android, iOS

- Protocols: MQTT, HTTPS

INTRODUCTION

A leading Germany-based manufacturer of industrial automation solutions approached Embien to develop an Industrial IoT device for real-time monitoring and control of industrial sensors over a large distance inside the factory. Embien took full responsibility for the turnkey development, delivering a robust, cost-effective solution that enhanced operational efficiency and security.

CHALLENGE

The Industrial IoT device required seamless integration with diverse sensors pH values, temperature, pressure, etc , secure connectivity, and a user-friendly interface. Key challenges included cost Optimization Achieving a low-cost design to enable mass deployment across large industrial facilities each spanning few kilometres.

SOLUTION

The Industrial IoT device was designed to collect data from industrial equipment, process it locally, and securely transmit it to a local gateway platform for consolidation and later push to cloud. Embien’s turnkey team delivered a comprehensive industrial IoT device development solution tailored to the customer’s requirements.

Industrial IoT Device Development

After thorough requirement analysis, Embien engineered a complete working solution incorporating multiple cutting-edge technologies. We evaluated various communication protocols including SigFox, LoRaWAN, and GPRS, ultimately selecting LoRa connectivity based on its optimal performance characteristics and reliability. The solution was enhanced with Bluetooth Low Energy (BLE) capabilities for precise asset tracking and sophisticated analog front ends for advanced signal processing.

Industrial IoT Device

NXP KW40 Design with LoRa connectivity

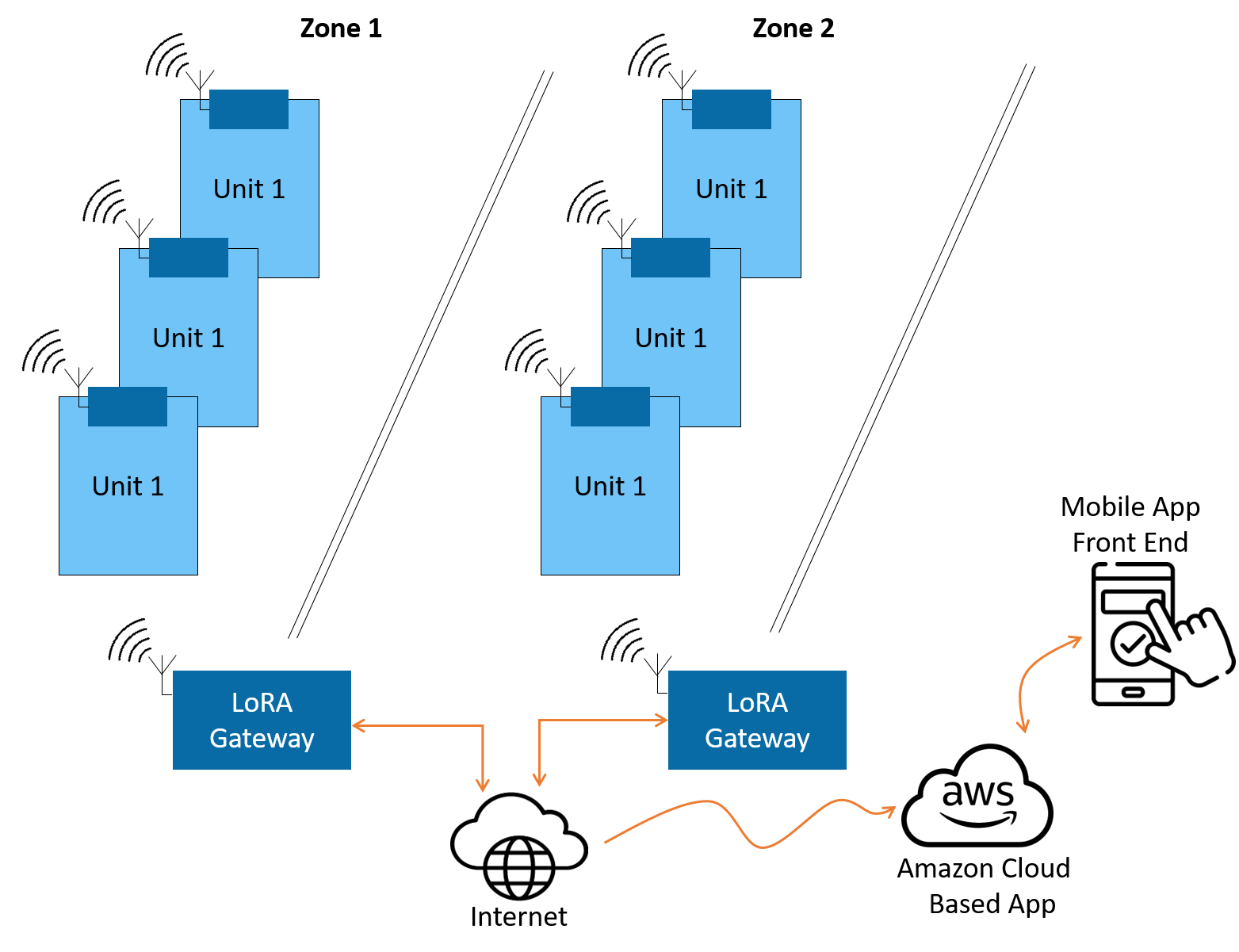

On detailed analysis, we decided for a Freescale/NXP Kinetis based design leveraging the on-chip BLE capability. Third-party LoRa module is integrated on to the solution enabling rapid deployment of the final design. LoRa gateways are strategically placed to maximize signal coverage and seamless communication. With in-built BLE functionality, the device could monitor the presence of technicians attending their job as they are provided with low-cost BLE Beacons for this purpose.

The design has integrated analog front ends that are capable of monitoring devices at high accuracy and precision. Periodically the critical sensor inputs are sampled, processed internally, and sent to the server via the LoRa gateway. It is also possible to explicitly send alarm and critical events to the server. The server also can read the data at any point of time. About user interface, few buttons are provided to be used by the technicians for various use cases. A couple of LED's are provided for indication purposes.

To conserve power all the modules are set to very low power states and unnecessary circuitry switched off when not used. Further the design is highly compact with 6 layer PCB design enclosed in a tiny IP68 enclosure. Antenna design was taken care well to avoid performance degradation due to multiple RF components present close together.

AWS IoT Cloud Application Design

As business intelligence contributes to the bottom line of the organization, the collected data over LoRa connectivity has to be stored, analyzed, and key information extracted. This calls for a cloud server running intelligent algorithms. The server part is developed using the Amazon Web Services server. An instance of a virtual server is used to handle the requests. The LoRa gateway stored the information temporarilty and pushed it to the cloud server. Custom algorithms are developed and insights obtained as needed by the customer. Embien also developed the web-based front end for the AWS IoT Cloud Application.

As a large number of such areas are present across geographies, grouping mechanisms are provided. Extensive reports are generated including the sensor values that are present across the location, values going off the limits, alarms and events, etc. Maintained reports are also provided along with when and how long the maintenance is done. Exact time stamps of any such events are also provided.

Industrial IoT Device System Deployment

Mobile App Development

Both Android and iOS based mobile apps were developed to present the collected information to the users. It also supports a server initiated over the air (OTA) upgrade of the firmware using LoRa communication enabling easier maintenance of the system. Embien incorporated user experience design in every part of the development activity thereby creating a user-friendly product.

After the industrial IoT device development was done, prototypes were manufactured, validated, and handed over to the customer for field trials, followed by technology transfer for mass production.

BENEFITS

This successful implementation demonstrates Embien's capability in delivering sophisticated IoT solutions that seamlessly integrate hardware, software, and cloud technologies. The system's modular architecture ensures scalability and future-readiness, while its robust design guarantees reliable performance in demanding industrial environments. Some advantages the customers obtained by our industrial IoT device development include

- Cost-Effective Design: Leveraged low cost NXK KW40 and COTS LoRa module to reduce costs.

- Prototyping: Supported advanced ADC with BLE and cloud platforms for versatile integration.

- Scalable Solution: Enabled deployment across diverse industrial applications.

- Robust Performance: Rugged design and rigorous testing ensured reliability in harsh environments.

- Speed: Leveraged powerful AWS IoT Cloud Application for faster development in data processing side.

CONCLUSION

The Industrial IoT device is now deployed across multiple industrial facilities in Europe, enhancing equipment monitoring and operational efficiency. Embien’s expertise in turnkey product engineering and IoT system integration delivered a secure, cost-effective solution. This project underscores Embien’s capability to drive innovation in industrial automation.